IQ, OQ, PQ

Installation Operational Performance

IQ, OQ, PQ – Water System Qualification

Complete Qualification for Pharmaceutical Water Systems

In pharmaceutical manufacturing, water systems are classified as critical utilities. Regulators expect that every new purified water (PW) or water for injection (WFI) system undergoes rigorous qualification before being released for GMP use. IQ, OQ and PQ provide the evidence that your system is correctly installed, operates as designed, and consistently delivers water that meets the requirements of the European Pharmacopoeia (Ph. Eur.), United States Pharmacopeia (USP), British Pharmacopoeia (BP) and Japanese Pharmacopoeia (JP).

At Honeyman, we deliver far more than paperwork. Our approach integrates the engineering expertise of Honeyman Water with the MHRA-approved GMP laboratories of Honeyman Laboratories. This unique capability allows us to manage the full lifecycle of qualification: from design and installation through to long-term monitoring and requalification.

What Are IQ, OQ and PQ?

Installation Qualification (IQ)

IQ confirms that your system has been installed correctly, following design documents, manufacturer specifications and cGMP requirements. This includes verification of design documentation against URS and P&IDs, review of material certificates (e.g., 316L stainless steel, weld logs, elastomer certifications), calibration records for sensors and transmitters, and confirmation of the correct installation of pumps, valves, heat exchangers and sanitisation systems. A complete documentation package is produced in line with EU Annex 15 and FDA expectations.

Operational Qualification (OQ)

OQ challenges the operational performance of the system under controlled conditions. It demonstrates that the equipment performs reliably within defined tolerances. This includes testing alarms and interlocks, confirming correct operation of automation sequences, verifying set-point ranges for temperature, pressure and flow, and simulating failure modes to confirm system response. Initial water sampling for key parameters such as conductivity, TOC and microbial counts is included.

Performance Qualification (PQ)

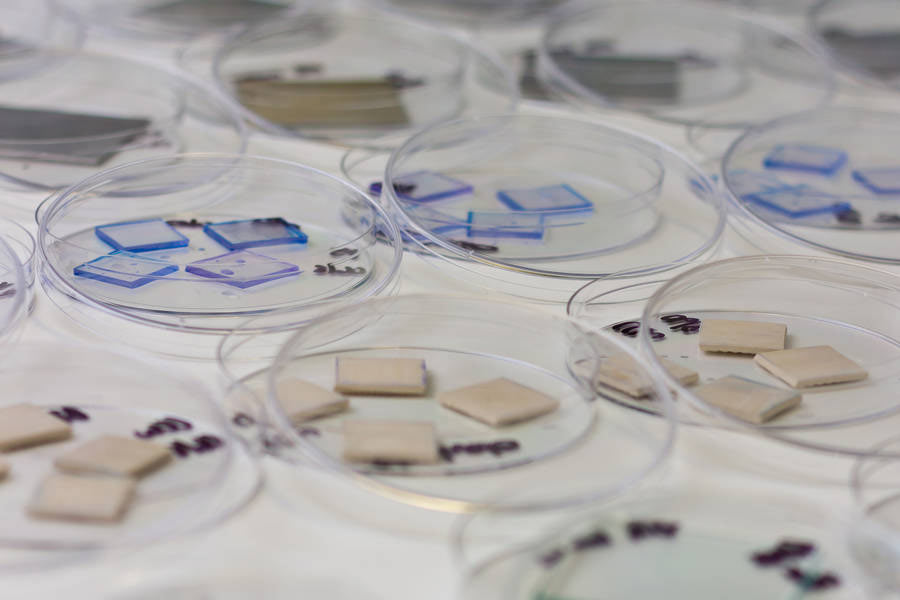

PQ provides assurance that the system consistently produces water of the required quality under normal operating conditions. A defined sampling plan is implemented across representative points of use and return loops, with testing covering conductivity, TOC, pH, nitrates, endotoxins (for WFI) and microbial enumeration. Results are trended to demonstrate system stability and compliance with Ph. Eur., USP, BP and JP standards. A final validation report confirms that the system is suitable for GMP production.

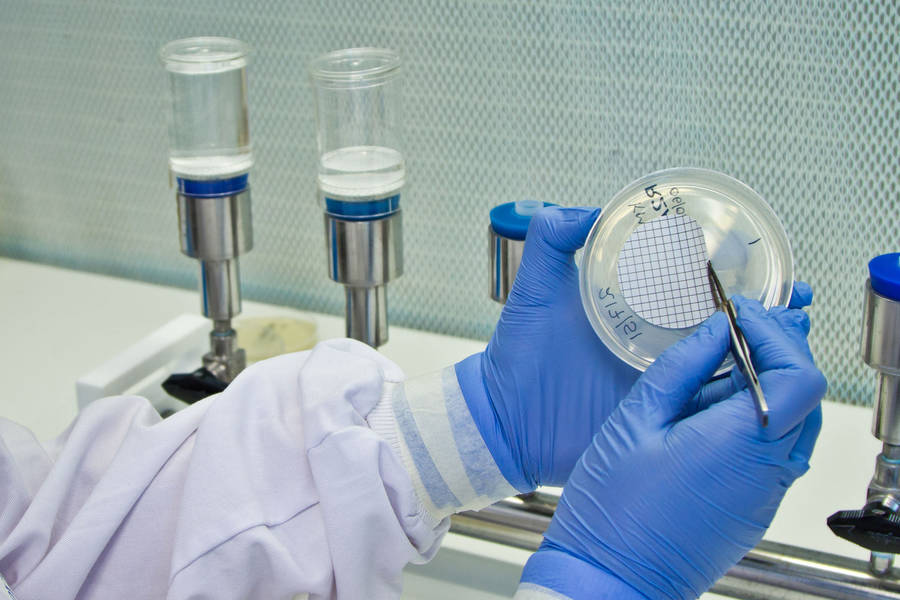

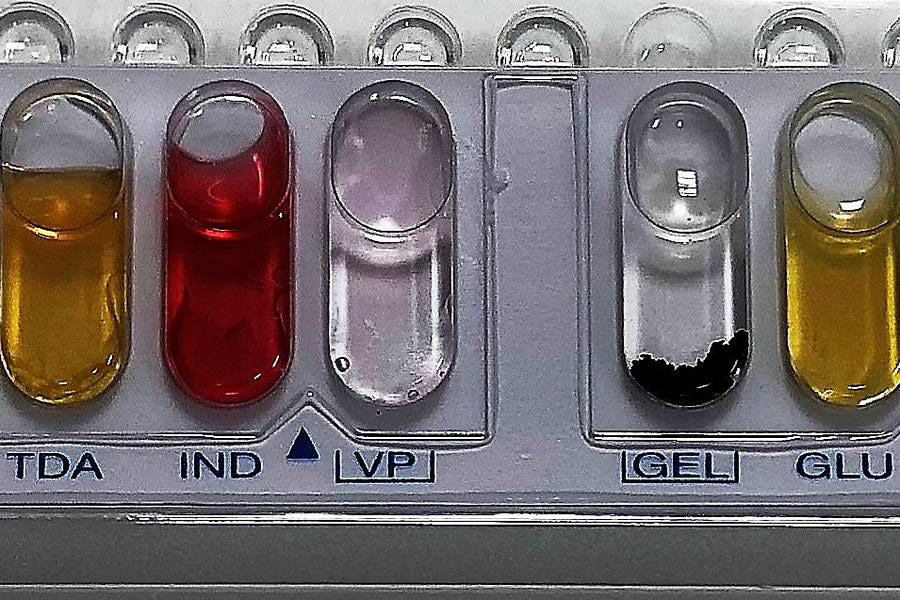

Laboratory Testing Integrated into Qualification

Our MHRA-approved laboratories provide the full suite of pharmacopoeial water tests required during qualification, including conductivity (Ph. Eur. 2.2.38, USP <645>), Total Organic Carbon (TOC), pH, nitrates, endotoxin testing (Ph. Eur. 2.6.14, USP <85>), microbial enumeration (TVC) and optional analyses such as chlorides, ammonia and elemental impurities.

All testing is carried out in-house by GMP-trained scientists using validated methods. Onsite GMP-trained samplers and validated transport ensure data integrity and reliability from collection through to reporting.

Documentation and Regulatory Compliance

Honeyman provides complete, audit-ready documentation for every stage of qualification. Deliverables include URS and design review support, IQ/OQ protocols and executed scripts, PQ sampling plans and raw data packs, and a final validation report with deviation management and CAPA recommendations. Documentation is prepared to withstand MHRA, EMA and FDA inspections.

Why Honeyman?

- Decades of experience qualifying water systems for leading pharmaceutical and biotech companies

- MHRA-inspected GMP laboratories specialising in chemical and microbiological water analysis

- Integration with Honeyman Water engineers for troubleshooting, upgrades and lifecycle support

- Ability to deliver both initial qualification and periodic requalification

- A lifecycle partner trusted to help clients prepare for and pass global inspections

Lifecycle Support Beyond Qualification

System qualification is not a one-off exercise. Regulators expect periodic review, requalification after major changes, and continuous monitoring of water quality. Honeyman supports the entire lifecycle with routine GMP water testing, trending and data interpretation, engineering consultancy for optimisation and upgrades, and training for operators and QC staff.

This means one partner for everything – from installation and qualification through to ongoing compliance and long-term reliability.

Partner with Honeyman

The risks of poor qualification are high: regulatory observations, delayed production and costly remediation. Honeyman provides a safer choice – combining engineering expertise, accredited laboratory testing and decades of experience in pharmaceutical water systems.

Contact our team today to discuss your IQ, OQ and PQ project and discover why Honeyman is one of the UK’s leading providers of complete lifecycle support for pharmaceutical water systems.

Our Customers: