Clean Steam Analysis

Pharmaceutical Steam Testing to HTM

Clean Steam Analysis

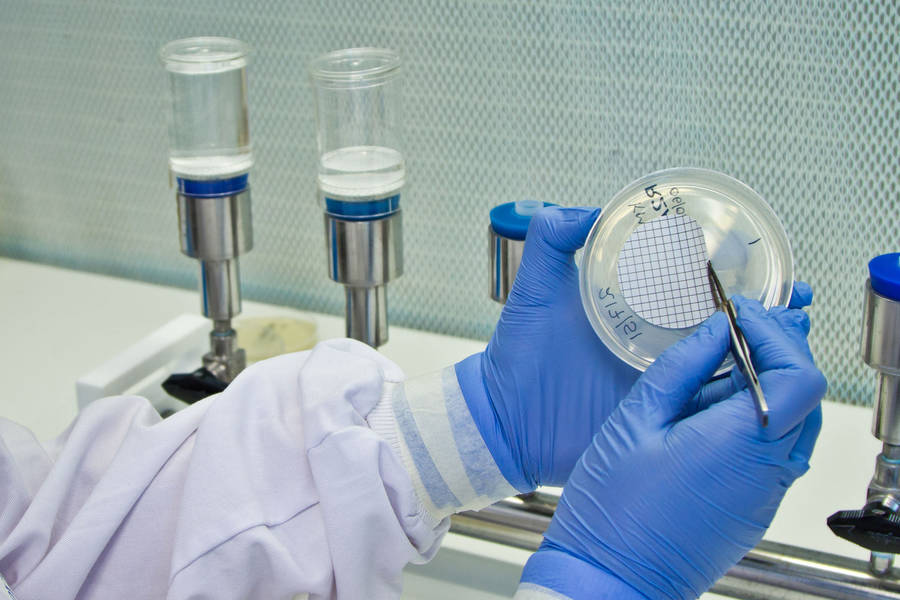

Clean steam is critical in pharmaceutical manufacturing and sterile services, where it is used for sterilisation, humidification, and direct contact with product-contact equipment. To ensure safety, regulatory compliance, and sterility assurance, clean steam must meet strict physical, chemical, and microbiological standards.

At Honeyman Laboratories, we provide full clean steam analysis, in partnership with our site engineers at Honeyman Water, in alignment with EN 285, HTM 01-01 (Part D), and pharmacopoeial requirements for water quality (WFI).

What We Test

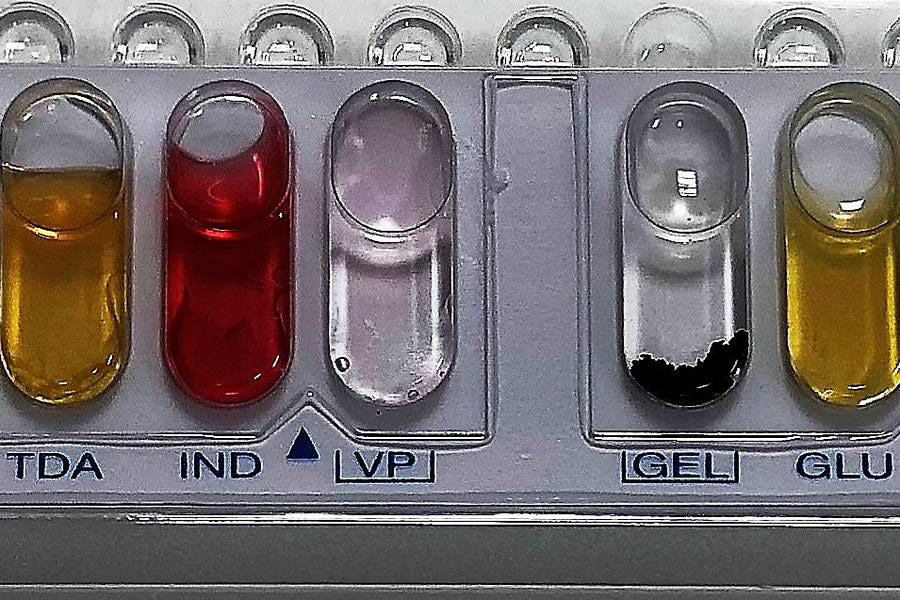

Our clean steam analysis covers all key parameters:

Physical quality (EN 285 criteria):

Why Clean Steam Testing Matters

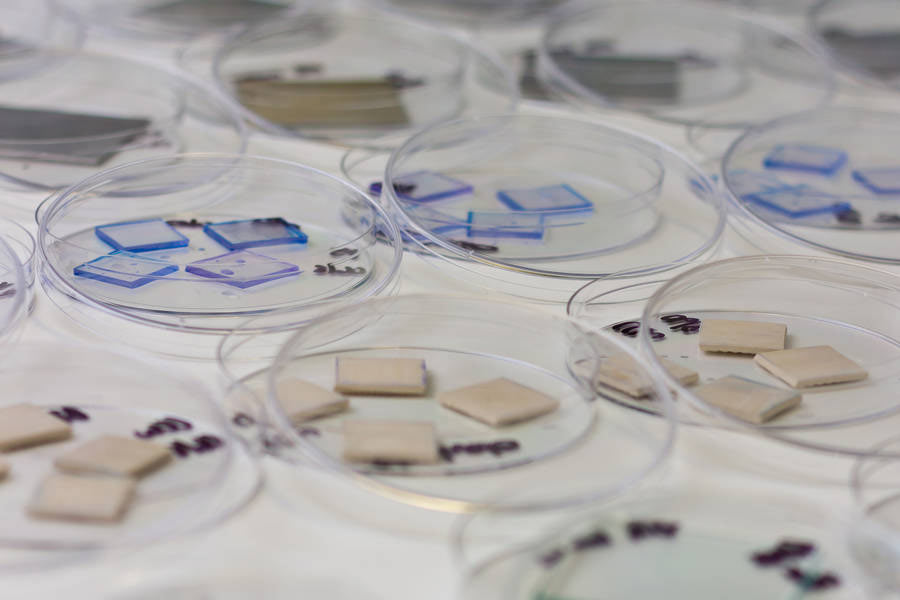

Non-compliant clean steam can cause failed sterilisation cycles, corrosion of product-contact equipment, contamination risk, and inspection findings. Routine analysis demonstrates control of your utility systems and ensures compliance with MHRA, EMA, FDA and HTM 01-01 expectations.

Why Choose Honeyman

Complete Lifecycle Support

From commissioning and qualification through to ongoing monitoring and troubleshooting, Honeyman offers full lifecycle support for your clean steam systems. Our expertise ensures your facility is inspection-ready, compliant, and safe.

Our Customers: