Cleaning Validation – Residue Analysis

Cleaning Validation Testing

Cleaning Validation – Residue Analysis

Analytical Chemistry for Cleaning Validation

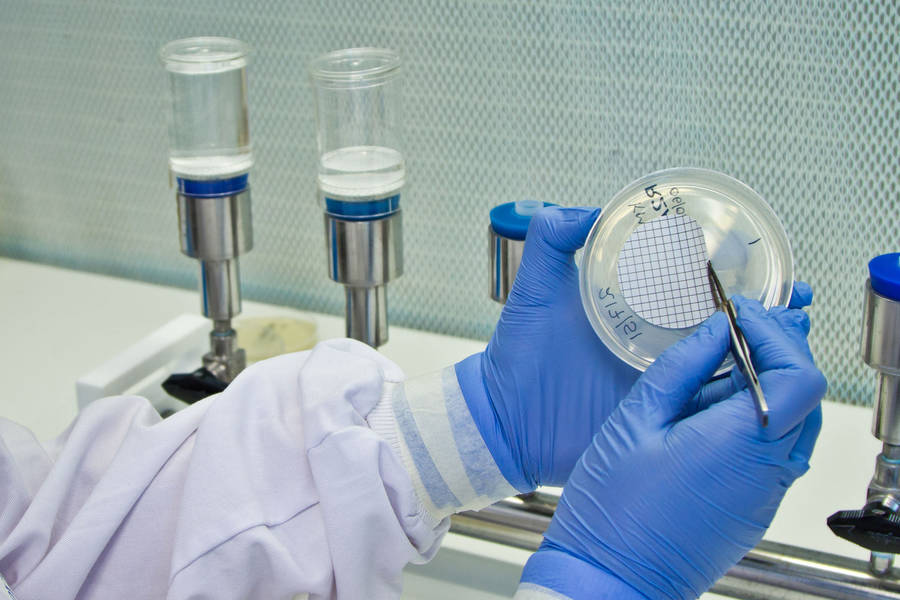

Cleaning validation is essential for ensuring that pharmaceutical manufacturing equipment is free from residual product, cleaning agents, and contaminants before the next production campaign. While swabbing and rinse sampling establish how equipment is sampled, the ultimate assurance comes from robust analytical chemistry methods that can detect even trace residues.

Honeyman Laboratories provides a full suite of residue analysis services designed specifically for cleaning validation programmes, ensuring compliance with EMA, FDA, and MHRA requirements.

Analytical Techniques We Offer

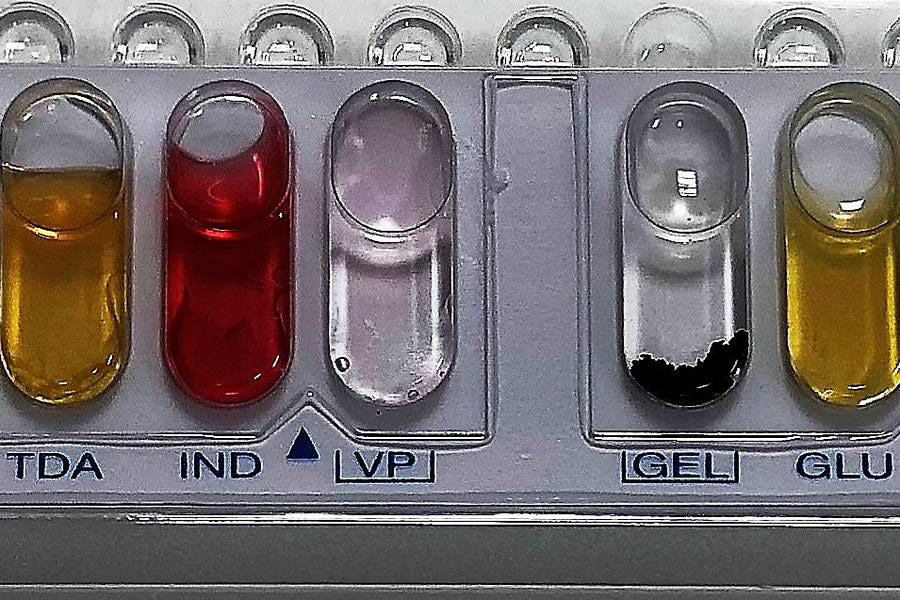

Our MHRA-approved GMP laboratories support cleaning validation by applying validated analytical techniques, including:

Recovery Studies and Acceptance Criteria

For cleaning validation results to be defensible, recovery studies are essential. We confirm that swabbing and rinse techniques reliably recover residues from relevant equipment surfaces. Acceptance limits are set in line with toxicology-based calculations, industry guidance (EMA, ISPE), and compendial expectations.

Bespoke and High-Risk Product Support

Standard compendial methods may not always be sufficient. For potent or high-risk actives, Honeyman develops bespoke analytical methods with the sensitivity and specificity needed to meet regulatory expectations.

Why Choose Honeyman?

Partner with Honeyman

Whether you need compendial testing or bespoke analytical method development, Honeyman Laboratories provides the residue analysis expertise to make your cleaning validation programme robust, compliant, and inspection-ready.

Our Customers: