Population Verification & Identification

Independent BI verification and consultancy for reliable, regulator-ready sterilisation validation.

Population Verification & Identification of Biological Indicators

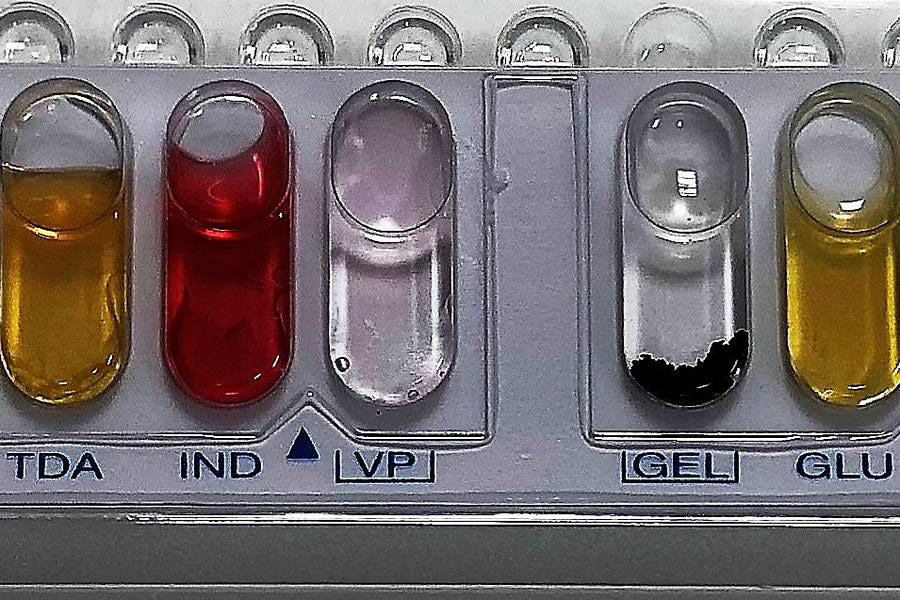

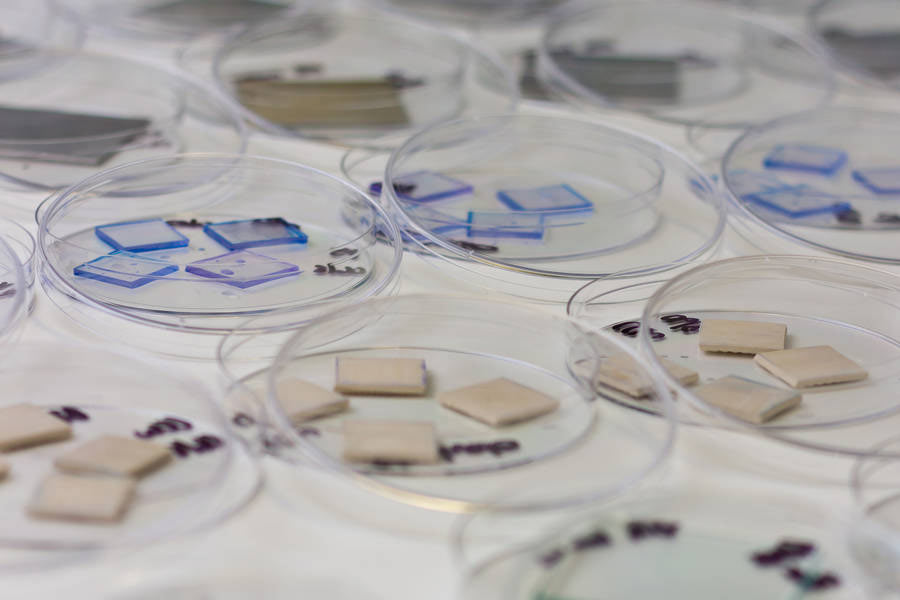

Biological indicators (BIs) are fundamental to sterilisation validation, providing the most resistant microorganisms to challenge and prove the effectiveness of sterilisation processes. Their reliability underpins Sterility Assurance Level (SAL) claims and is a regulatory expectation in GMP environments.

What Do We Mean by Population Verification & Identification?

Both procedures are required by Ph. Eur. 2.6.12 / 2.6.13, USP <55>, and equivalent compendial references.

Why It Matters

If BI populations are overstated, a sterilisation process may appear more effective than it really is. If species identity is misrepresented, resistance profiles may not match the intended challenge. Either scenario risks:

Honeyman’s BI Verification Expertise

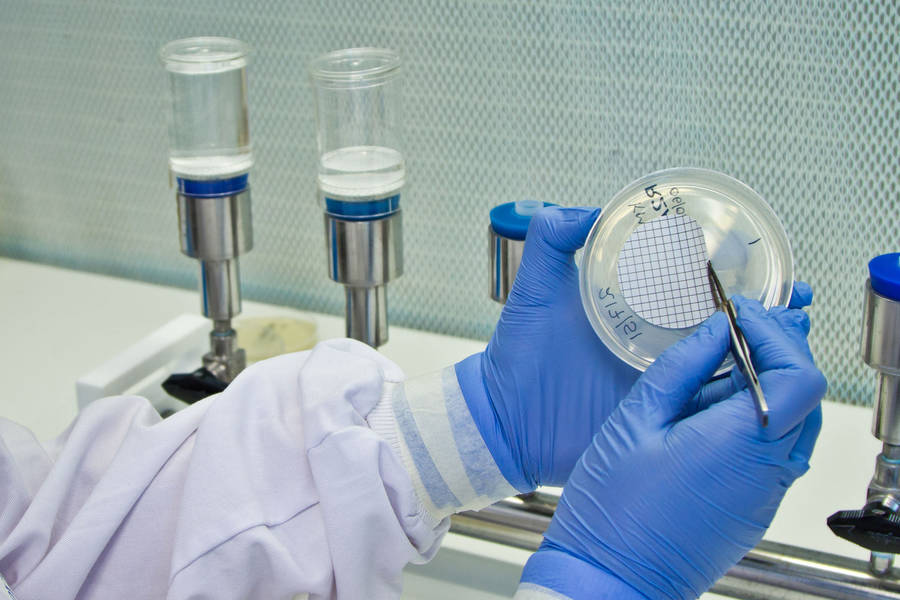

Honeyman Laboratories is one of the UK’s few independent, MHRA-approved contract laboratories offering a complete BI verification service. We provide:

Beyond Testing – Consultancy & Support

Our expertise extends beyond the laboratory. We offer:

Why Choose Honeyman

Honeyman Laboratories delivers not just population counts and species IDs, but the confidence that your sterilisation validation is defensible, compliant and inspection-ready.

Our Customers: